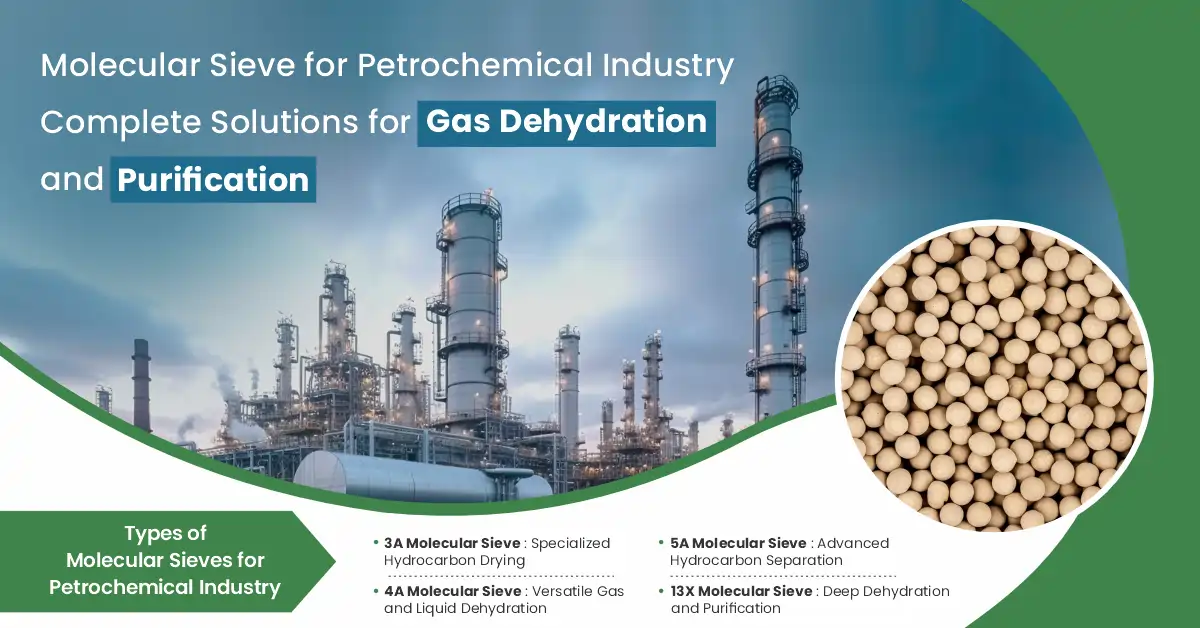

Molecular Sieve for Petrochemical Industry: Complete Solutions for Gas Dehydration and Purification

Introduction to Industrial Molecular Sieve Adsorbents

The petrochemical industry demands the highest standards of purity and efficiency in gas and liquid processing. As a leading molecular sieve for petrochemical industry supplier, advanced adsorbent solutions play a critical role in ensuring optimal performance across refinery applications, natural gas processing, and hydrocarbon separation. zeolite adsorbents for gas drying have become indispensable tools for maintaining product quality, protecting equipment, and meeting stringent industry standards.

Zeolite molecular sieve suppliers provide specialized crystalline aluminosilicate materials with uniform pore structures that selectively adsorb molecules based on size and polarity. These industrial molecular sieve beads suppliers offer solutions that address the most challenging dehydration and purification requirements in petrochemical operations, from natural gas dehydration to hydrogen purification and beyond.

Understanding Molecular Sieve Technology for Petrochemical Applications

What Makes Molecular Sieves Essential?

Molecular sieve dehydration petrochemical processes rely on the unique three-dimensional structure of zeolite materials. These synthetic aluminosilicates possess microporous structures with pore diameters measured in Angstroms (Å), allowing them to trap specific molecules while excluding others. This selective adsorption capability makes them superior to traditional desiccants for critical petrochemical applications.

The pore size determines which molecules can be adsorbed, making different molecular sieve types suitable for specific applications. With pore diameters ranging from 3Å to 10Å, these materials can target water molecules, carbon dioxide, hydrogen sulfide, mercaptans, and various other impurities that compromise product quality and process efficiency.

Types of Molecular Sieves for Petrochemical Industry

-

3A Molecular Sieve: Specialized Hydrocarbon Drying

3A molecular sieve features a pore size of approximately 3 Angstroms, specifically designed for applications requiring the exclusion of larger molecules. This makes it ideal for drying unsaturated hydrocarbons including cracked gas, propylene, butadiene, and acetylene, ethanol dehydration in biofuel production, petroleum gas purification, desiccation of alkenes in oil refining, and polar solvent drying including ethanol.

The small pore size effectively adsorbs water molecules while preventing the co-adsorption of hydrocarbons, making it perfect for maintaining product purity in sensitive petrochemical processes. The bulk density ranges between 0.60-0.68 g/ml, and the material exhibits excellent thermal stability for repeated regeneration cycles.

-

4A Molecular Sieve: Versatile Gas and Liquid Dehydration

4A molecular sieve possesses a slightly larger pore opening of approximately 4 Angstroms, allowing it to adsorb water, ammonia, and carbon dioxide. Key applications include natural gas dehydration and CO2 removal, drying LPG and other petrochemical liquids, purification of inert and atmospheric gases, refrigerant drying, and air separation processes.

This versatile zeolite gas dehydration solution effectively removes moisture to prevent pipeline hydrate formation, equipment corrosion, and operational disruptions. Its excellent adsorption selectivity makes it suitable for maintaining purity in both polar and non-polar compounds.

-

5A Molecular Sieve: Advanced Hydrocarbon Separation

5A molecular sieve petrochemical application centers on its 5 Angstrom pore size, which enables the separation of normal paraffins from branched-chain and cyclic hydrocarbons. Primary uses include 5A molecular sieve hydrocarbon separation in refineries, molecular sieve for hydrogen purification processes, production of high-purity hydrogen for refining operations, normal paraffin/iso-paraffin separation, oxygen absorption in PSA and VPSA systems, nitrogen separation from air in petrochemical plants, and natural gas drying and purification.

The larger pore size allows Zeolite 5A supplier products to adsorb bigger molecules, making them invaluable for commercial air, petroleum, and gas refining applications. They are extensively used in producing ultra-pure hydrogen for hydrocracking and hydrotreating units, where purity levels exceeding 99.9% are routinely achieved.

-

13X Molecular Sieve: Deep Dehydration and Purification

13X molecular sieve petrochemical application dominates where deep drying and removal of larger molecules is required. With a pore size of 8-10 Angstroms, these sieves offer molecular sieve for natural gas dehydration to moisture levels below 1 ppmv, removal of sulfur compounds from LPG and natural gas, CO2 and H2S removal from gas streams, mercaptan removal in LPG sweetening applications, air separation in cryogenic plants, deep drying of petrochemical liquids and gases, and removal of trace impurities in refinery applications.

The 13X molecular sieve features the highest adsorption capacity among standard zeolite types, making it essential for 13X zeolite for refinery applications requiring ultra-low moisture specifications. Its ability to remove both water and acid gases simultaneously makes it particularly valuable in integrated purification systems.

Critical Applications in Petrochemical Plants

-

Natural Gas Processing and Dehydration

Molecular sieve for natural gas dehydration prevents catastrophic pipeline blockages caused by ice formation and methane clathrate crystals. Nature has blessed us with uncountable resources; some can be used directly, while others need to undergo a purification process. This is true for natural gas as well. To harness its full potential, natural gas must undergo a purification process in gas processing plants to remove impurities that can hinder its performance.

Whether it's being used for power generation, petrochemical production, or transportation, ensuring its purity is essential. Molecular sieve for petrochemical plants uses both 4A and 13X types to achieve ultra-low dewpoints required for cryogenic processing, LNG production, and NGL extraction. In natural gas treatment, desiccants such as molecular sieves are the best choice for achieving high purity levels because they are highly effective, selective, and regenerative, which makes them a cost-effective solution for long-term use.

-

Hydrogen Purification for Refinery Operations

Molecular sieve for hydrogen purification has become increasingly critical as refineries process heavier, more sulfur-rich crude oils requiring extensive hydro processing. The 5A molecular sieve supplier provides materials specifically designed to remove moisture, CO2, and trace hydrocarbons from hydrogen streams, achieving purity levels exceeding 99.999%. This ensures optimal catalyst performance and prevents poisoning that would otherwise reduce conversion rates and increase operating costs in hydrocracking and hydrotreating units.

-

Refinery Gas Drying and Sweetening

Molecular sieve for refinery applications extends across multiple process units. Petrochemical gas drying solutions using molecular sieves protect expensive catalysts, prevent corrosion, and ensure product specifications are consistently met. These systems are used to dry and purify gases and liquids, ensuring the removal of impurities and moisture, which is required for maintaining product quality and preventing equipment damage throughout petrochemical operations.

-

LPG and NGL Processing

Molecular sieve dehydration petrochemical systems prevent freezing during cryogenic separation and ensure product meets commercial specifications. 13X molecular sieve excels at removing both water and mercaptans from LPG streams in a single operation, reducing capital and operating costs compared to sequential treatment systems.

-

Compressed Air Drying

Molecular sieves are effective in drying compressed air, reducing the dew point to very low levels. This is important for preventing moisture-related issues in pneumatic systems used throughout petrochemical facilities. Molecular sieve adsorbents for gas drying ensure that compressed air systems operate efficiently without moisture contamination.

Molecular Sieve Regeneration in Petrochemical Plants

Molecular sieve regeneration restores adsorption capacity using Thermal Swing Adsorption (TSA), heating beds to 175–315°C with dry gas purge on 8–24 hour cycles. Pressure Swing Adsorption (PSA) exploits pressure changes for rapid cycling, while Vacuum PSA (VPSA) enhances efficiency and lowers energy use. Hybrid systems combining heating, pressure reduction, and purging optimize regeneration, reducing energy costs by 20–30% while maintaining excellent sieve performance across petrochemical applications like oxygen concentration, hydrogen purification, and air separation.

Optimizing Regeneration Cycles

Effective molecular sieve regeneration balances several factors including regeneration temperature that's high enough to drive off adsorbed species but not so high as to cause structural degradation, gradual heating rates to prevent thermal shock and bed shrinkage, proper cooling procedures before returning to service to prevent moisture readsorption, purge gas selection using dry nitrogen or treated natural gas to prevent contamination during regeneration, and cycle duration optimized to balance throughput against energy costs.

Properly designed regeneration systems maximize sieve life while minimizing energy consumption and downtime, critical factors in continuous petrochemical operations.

When buying molecular sieves for gas dehydration, quality factors drive long term performance. High adsorption capacity reduces bed size and regeneration frequency, lowering costs. Premium sieves achieve water capacities of 20–22% for 4A and 26–28% for 13X.

Working with a Zeolite Molecular Sieve Supplier

Partnering with an experienced zeolite molecular sieve supplier ensures technical expertise, quality assurance, tailored formulations, reliable supply, competitive pricing, and strong after sales support. Leading suppliers maintain extensive inventories of standard beads while offering custom manufacturing for specialised petrochemical applications, guaranteeing facilities access to exact materials required for optimal performance, efficiency, and long term operational reliability.

Conclusion

As a trusted supplier, advanced molecular sieve solutions with novel zeolite frameworks, hybrid adsorbents, and intelligent controls enhance efficiency. With heavier crudes, rising hydrogen demand, and stricter regulations, 3A, 5A, and 13X sieves remain indispensable for dehydration, purification, and refinery applications, ensuring reliability, selectivity, and sustainable petrochemical processing excellence.